Fan Coil Units Manufacturer: Carrier

Model#: 18RVT3-HP

Project Scope of Work:

- Rejuvenate the coils;

- Replace the fiber insulation with foam anti-microbial insulation;

- Refurbish the condensate pans and coat with an impermeable epoxy;

- Replace the PSC motors with high efficiency EC motors; and

- Replace the control valves as needed.

Challenges: The coils were impacted with dirt, debris and other organic materials, which limited heat transfer and restricted airflow to below the manufacturer’s design specifications. This combination resulted in the rooms not being conditioned correctly. Additionally lack of airflow differentiation between high and low fan speeds impeded efficient operation, wasted energy, and negatively impacted guest satisfaction. The condensate pans and insulation were aged and beyond their useful life.

The site survey found that the average fan coil unit performance was not in line with original design specifications:

- The coil temperature was above 55 degrees on 87% of the units.

- The supply temperature was above 60 degrees on 89% of the units.

- Airflow on the 400 CFM design averaged 340 CFM.

- Airflow on the 600 CFM design averaged 508 CFM.

The site survey determined that the coils and fins were in good condition and did not need to be replaced. The site survey found that less than 10% of the control valves were bypassing requiring replacement.

Solutions:

AirRevive advised that the unit’s life could be extended and operation brought to like new through AirRevive’s cabinet refurbishment, coil rejuvenation, EC motor retrofit and control valve replacement services.

Results

- 400 CFM units’ high fan airflow increased by an average 26% from 340 CFM to 427 CFM.

- 600 CFM units’ high fan airflow increased by an average 22% from 508 CFM to 619 CFM.

- Coil temperature dropped by an average 4.7 degrees from 56.4℉ to 51.6℉.

- Supply temperature dropped by an average 5.1 degrees from 62.2℉ to 57.1℉.

- Sound reduced by an average 9dB from an average 61dB to 52dB, halving the noise produced by the units.

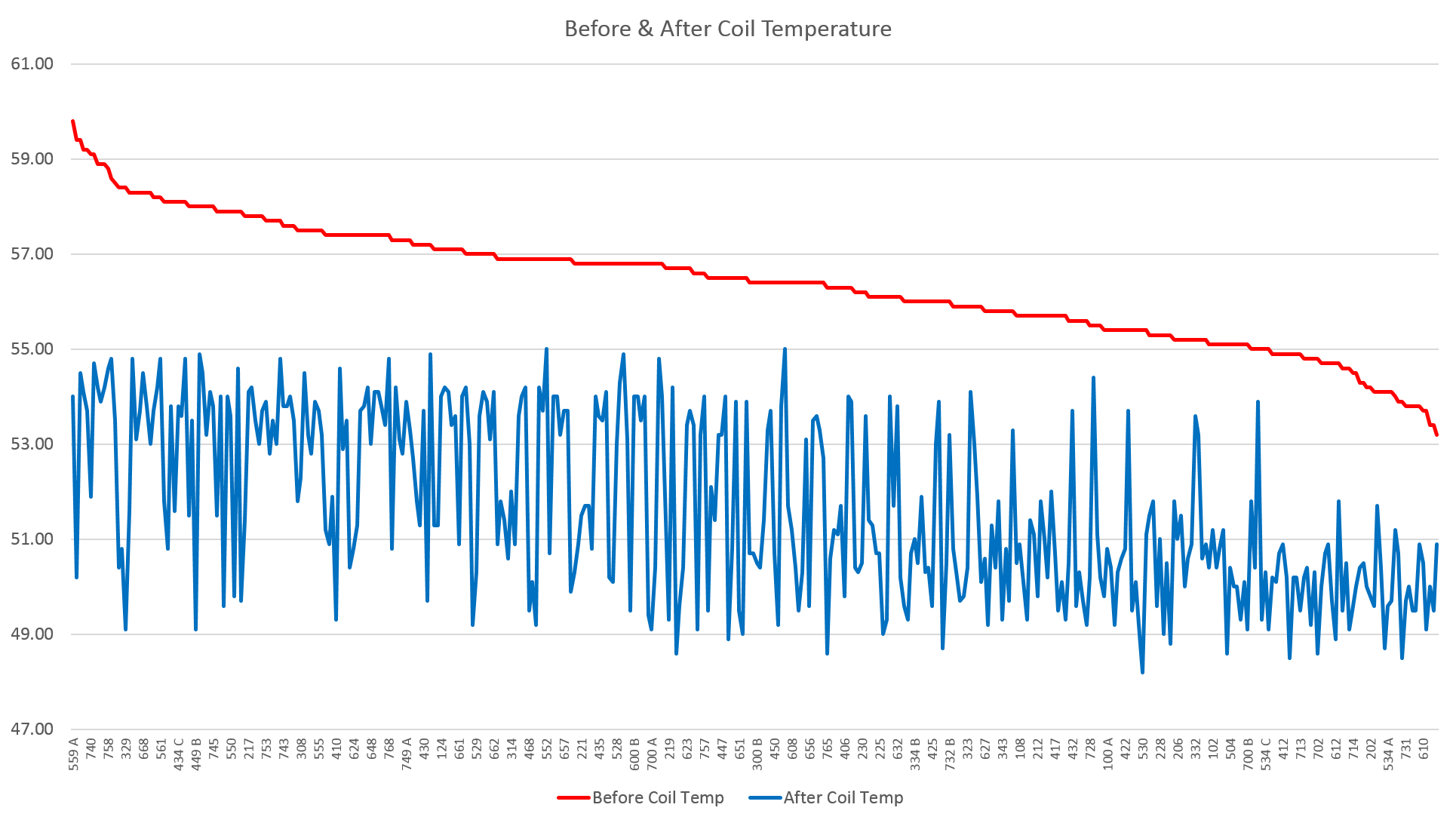

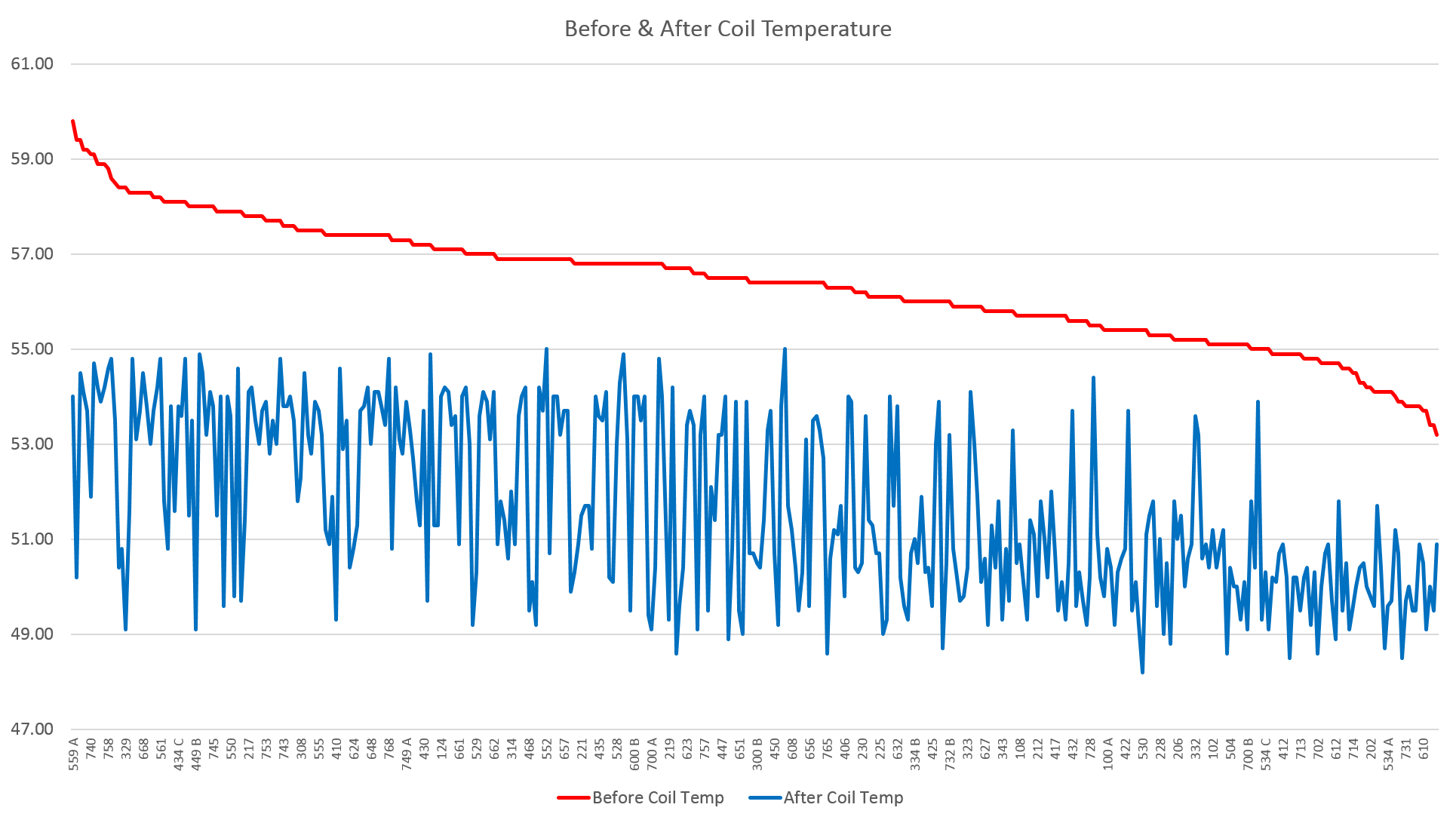

Before & After Coil Temperature

Summary: Coil temperature dropped by an average 4.7 degrees from 56.4℉ to 51.6℉.

The graph below is sorted by coil temperature from high to low before coil rejuvenation and EC motor retrofit. The horizontal axis represents the unit’s room number.

The red line demonstrates that before the service the coil temperature ranged from 59.8℉ to 53.2℉. The average coil temperature was 56.4℉.

The blue line demonstrates that after the coil rejuvenation and EC motor retrofit 100% of the unit’s coil temperature dropped below 55℉ and 80% of the unit’s coil temperature dropped below 53 degrees. The average coil temperature after service was 51.6℉.

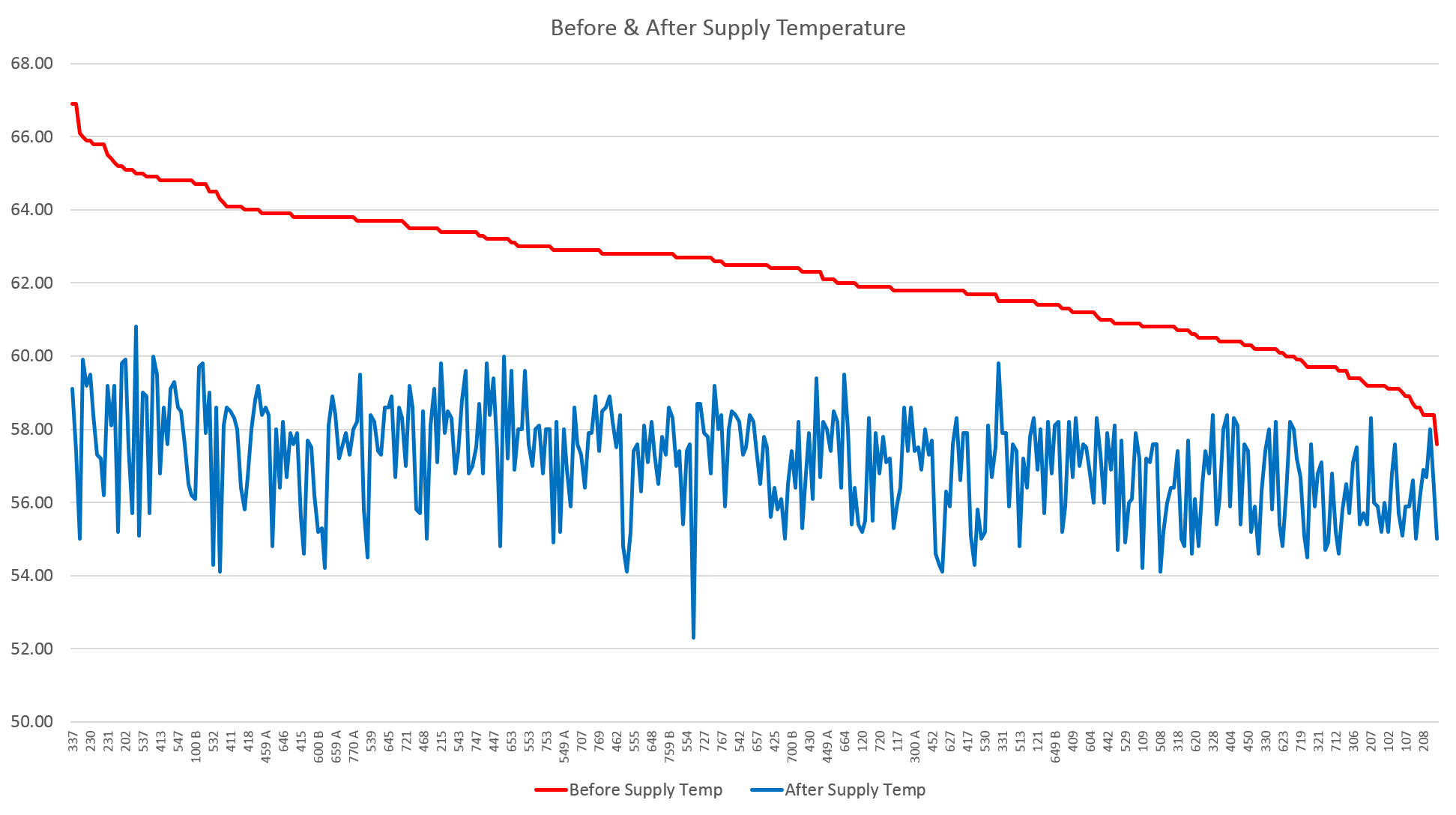

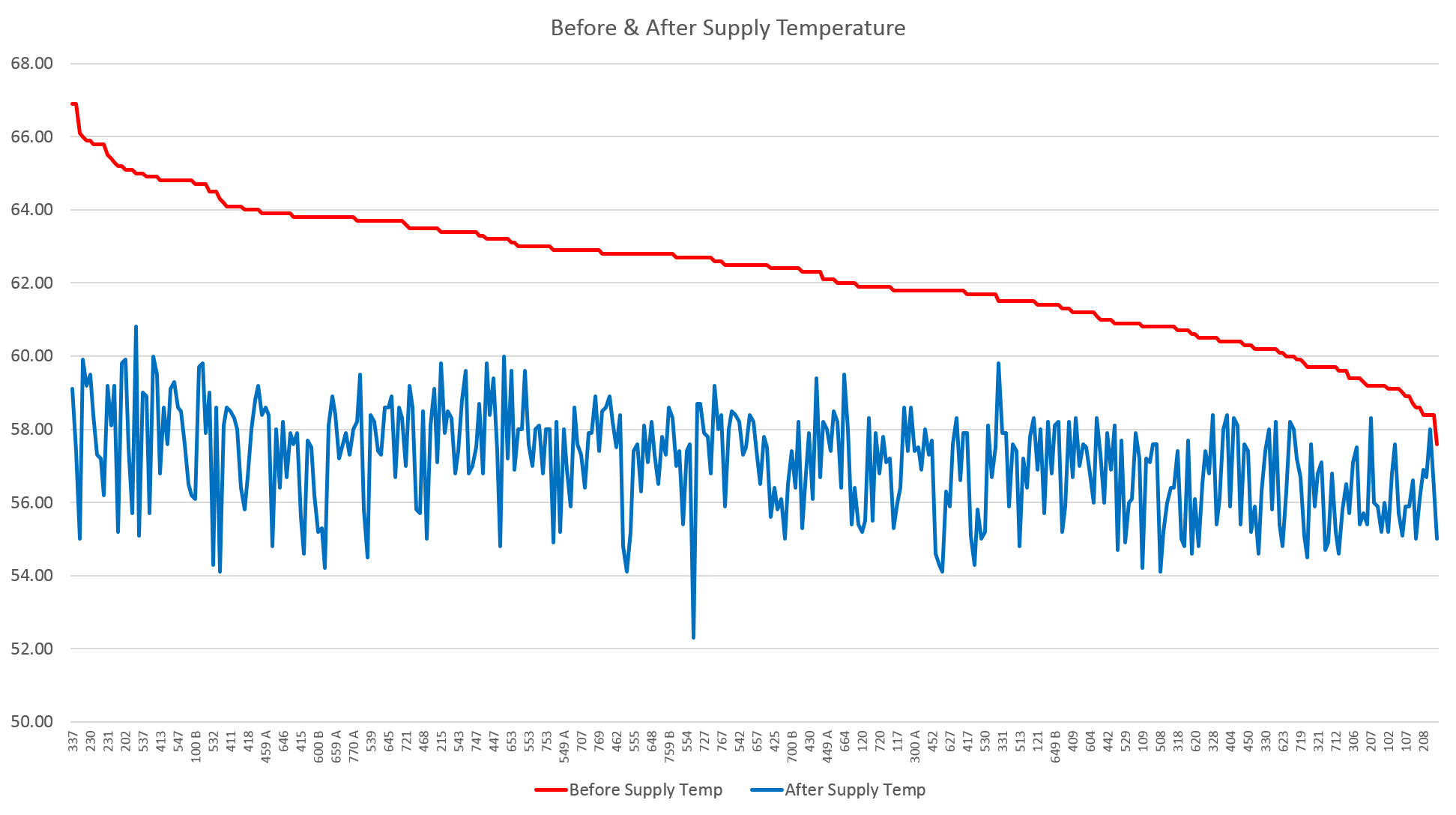

Before & After Supply Temperature

Summary: Supply temperature dropped by an average 5.1 degrees from 62.2℉ to 57.1℉.

The graph below is sorted by supply temperature from high to low before coil rejuvenation and EC motor retrofit. The horizontal axis represents the unit’s room number.

The red line demonstrates that before the service the supply temperature ranged from 66.9℉ to 57℉. The average supply temperature was 62.2℉.

The blue line demonstrates that after the coil rejuvenation and EC motor retrofit 100% of the unit’s supply temperature dropped below 60℉. The average supply temperature after service was 57.1℉.

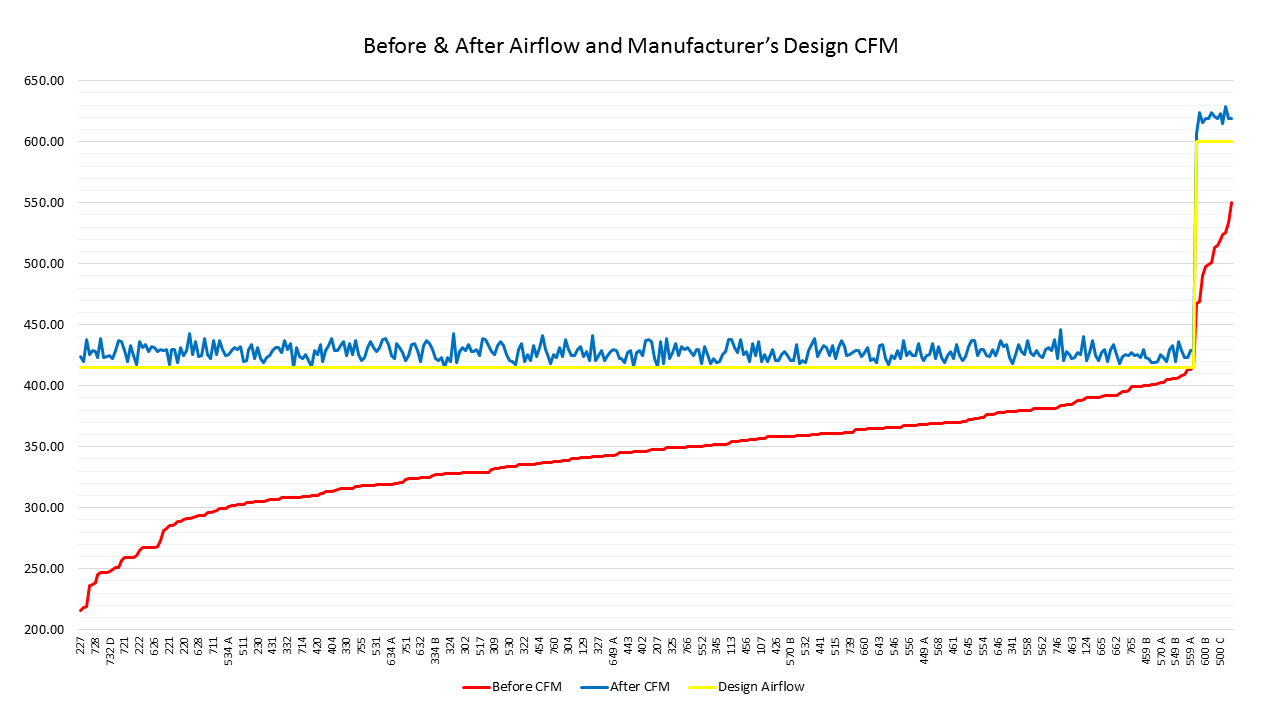

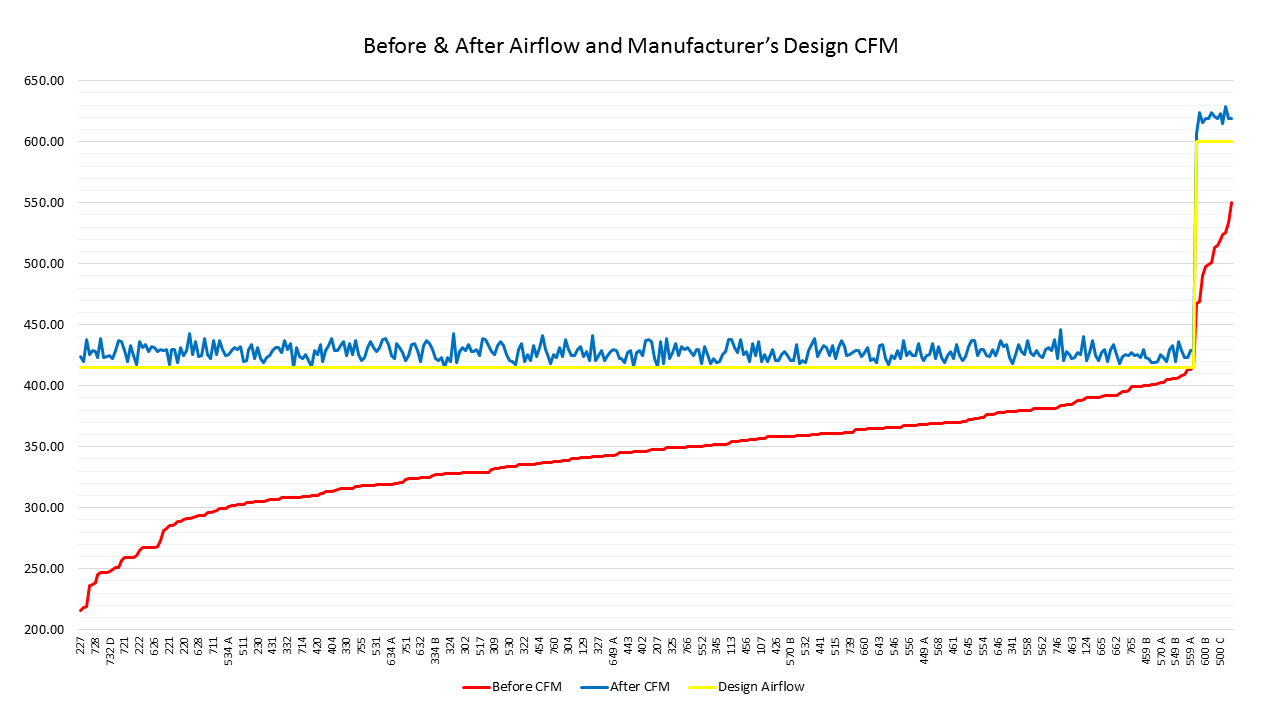

Before & After Airflow Data

Summary: 400 CFM design unit’s high fan airflow increased by an average 26% from 340 CFM to 427 CFM. 600 CFM design unit’s high fan airflow increased by an average 22% from 508 CFM to 619 CFM.

The graph below is sorted by airflow from low to high before coil rejuvenation and the EC motor retrofit. The horizontal axis represents the unit’s room number. The yellow line shows the manufacturer’s design specification.

The red line is airflow before refurbishment and the EC motor retrofit. The red line’s slope up to the right demonstrates that the 400 CFM design unit’s airflow before service ranged from 215 to 429 CFM. The 600 CFM design unit’s airflow ranged from 467 to 550 CFM.

The blue line demonstrates that after the coil rejuvenation and EC motor retrofit the airflow is programmed to the manufacturer’s design specifications. Each 400 CFM design unit’s high fan airflow was programmed within 10% above the airflow design specifications between 400 and 440 CFM, with an average airflow of 427 CFM. Each 600 CFM design unit’s high fan airflow was programmed to the design specifications between 580 and 640 CFM, with an average airflow of 619 CFM.

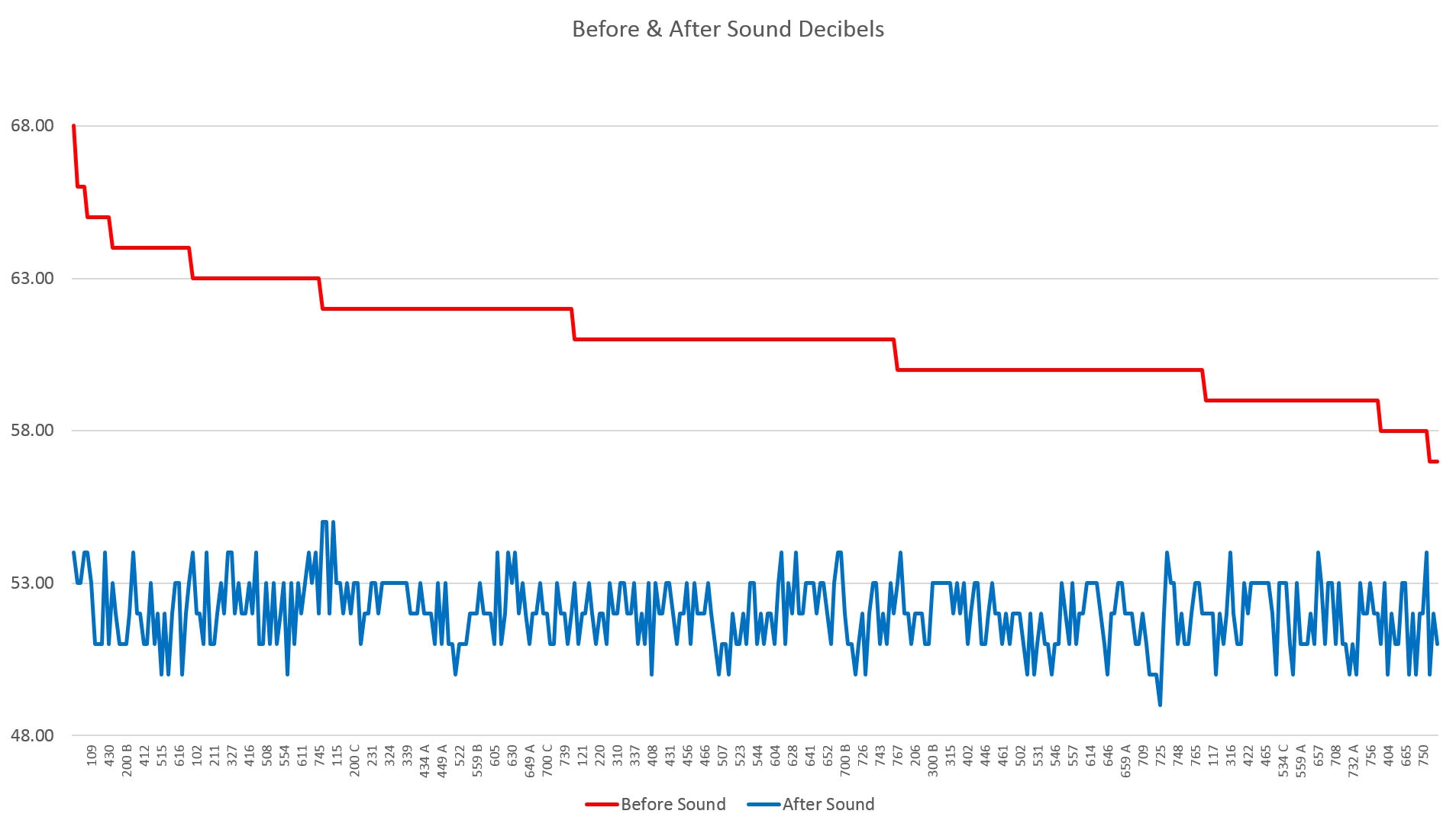

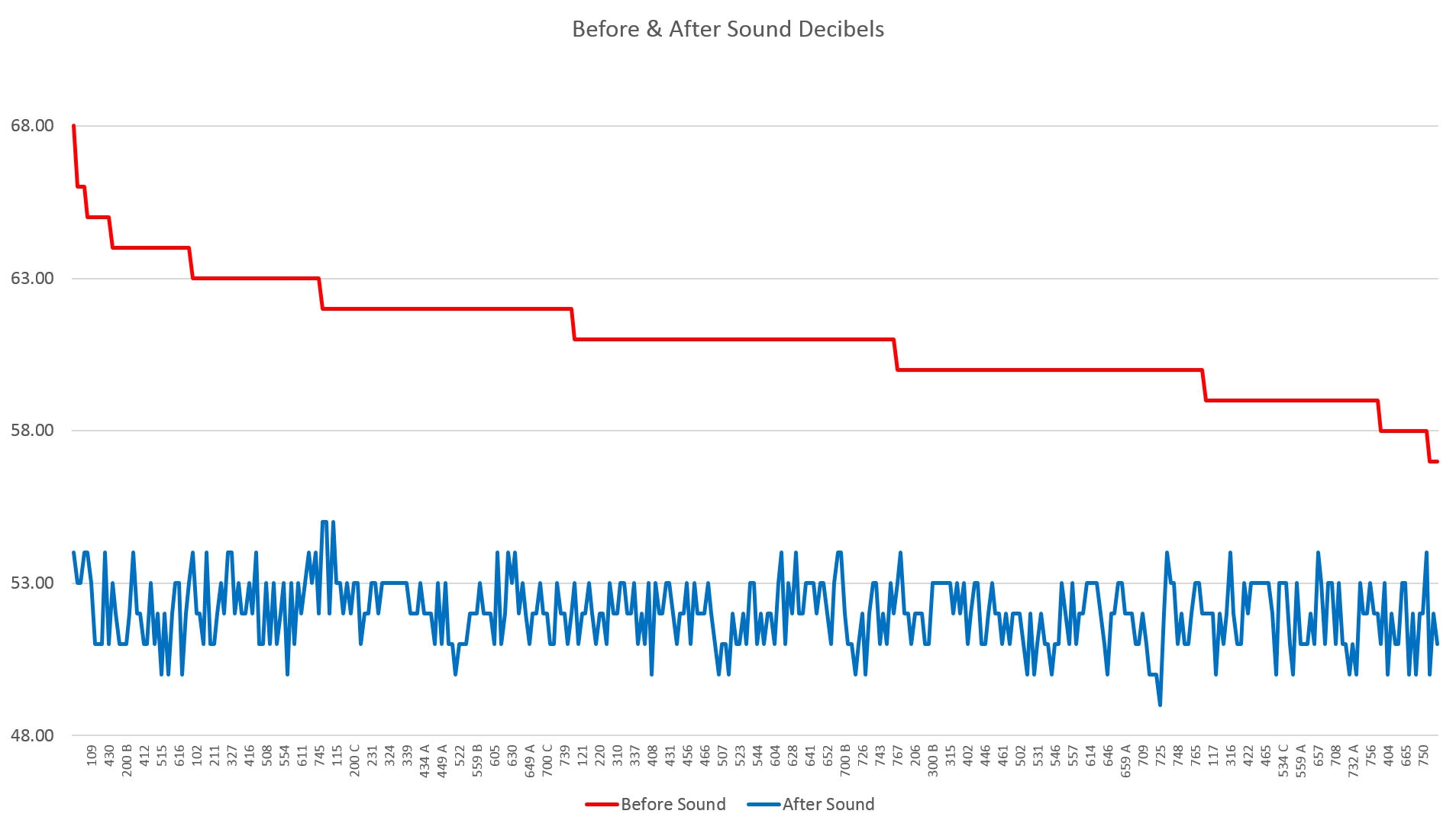

Before & After Sound Decibels

Summary: Sound was reduced by an average 9dB from an average of 61dB to 52dB. The 9db sound reduction equates to the unit’s noise being half as loud after coil rejuvenation and EC motor retrofit when compared to before.

The graph below is sorted by sound decibels from high to low before refurbishment and EC motor retrofit. The horizontal axis represents the unit’s room number.

The red line represents sound decibels before refurbishment and EC motor retrofit. The red line’s slope down to the right demonstrates that the units’ sound decibels before service ranged from 68dB to 57dB.

The blue line demonstrates that after service 100% of the unit’s sound is lower than 54db, with an average of 52dB. 52dB is comparable to a quiet street. The blue line demonstrates that after the refurbishment and EC motor retrofit, the units were quiet.