The re-commissioned unit consumes the equivalent of $84 less energy annually, approximately $58,800 in total!

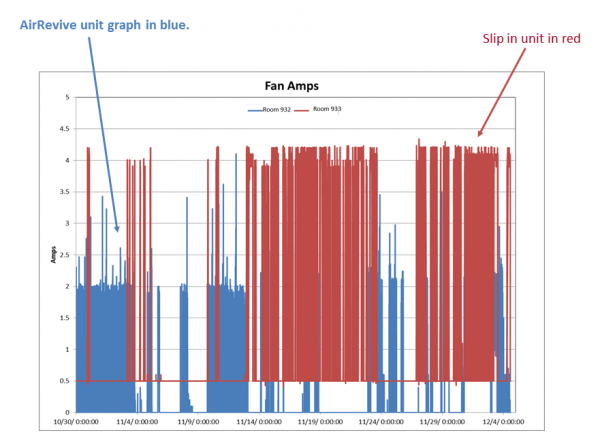

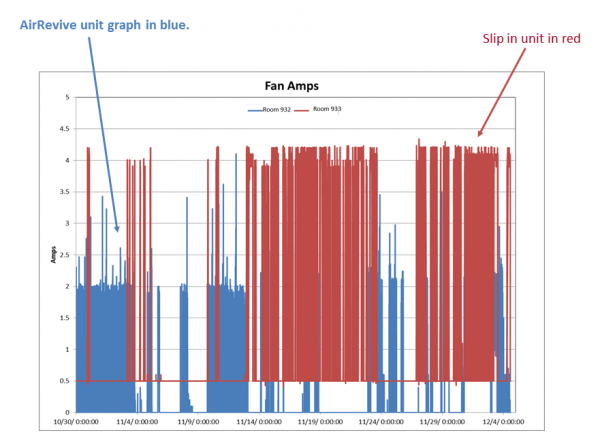

In the graph below, the AirRevive re-commissioned unit in room 932 is represented in blue.

The AirRevive re-commissioned unit’s averaged fan amps, when the unit was operating fan amps, was 1.5 amps.

The slip-in unit in room 933 is represented in red.

The slip in unit’s averaged fan amps, when the unit was operating fan amps, was 4 amps.

Click on graph to enlarge.

If both units run continuously for the year, the re-commissioned unit in room 932 consumes 675 watts less than the unit in 933.

At the Washington, DC electric rate of $13 cents/kwh, room 932 costs $84 less annually to run. Re-commissioning 700 guest room units will save approximately $58,800 in electricity annually.

Savings assume an energy rate of $0.125/kWh, 8760 possible hours/year of operation.

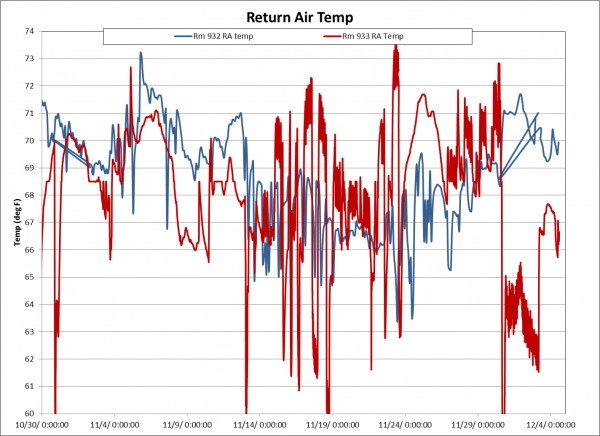

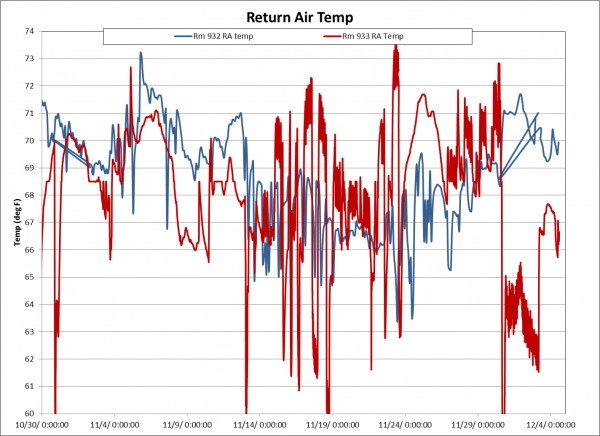

ROOM (RETURN) TEMPERATURE

The graph below illustrates the room (return) temperature.

The AirRevive re-commissioned unit in room 932 is represented in blue.

The manufactured slip-in in room 933 is represented in red.

Return Air Temperature Graph

Click on graph to enlarge.

The manufactured unit represented in red produced guest room temperature demonstrates a wide band fluctuating between 60 and 74 degrees. It can be concluded the low temperature points on the bands represent a ramp up of very cold air before settling to the intended temperature set.

The AirRevive re-commissioned unit represented in blue produced guest room temperatures that fluctuated narrowly between 65 and 73 degrees. It can be concluded the accurate temperature set is reached quickly maintaining a comfortable guest room environment and using less energy.

The data demonstrates the re-commissioned unit maintained guest room temperature with a 6 degree variance while the slip-in unit produced guest room temperature with a 14 degree variance.