CUSTOMER: Full Service Marriott

LOCATION: Washington, DC

INDUSTRY: Hospitality

AIRREVIVE SERVICE: Fan coil unit refurbishment and re-commissioning

FAN COIL UNITS: 1984 Unilux SC600, Vertical, 4-Pipes

CUSTOMER: Full Service Marriott

LOCATION: Washington, DC

INDUSTRY: Hospitality

AIRREVIVE SERVICE: Fan coil unit refurbishment and re-commissioning

FAN COIL UNITS: 1984 Unilux SC600, Vertical, 4-Pipes

WHAT THE CLIENT NEEDED

As a popular contemporary airport hotel in one of the busiest cities in the world, this full service Marriott has business, leisure and contracted airplane crew to accommodate. The hotel that runs at 96+% occupancy year round needed to upgrade or replace their guest room fan coil units. The units were not properly operating to cool and heat. The challenge for this airport property was it could not give up guest rooms. The age of the property and the fan coil units was also a challenge.

Built in 1984, the two buildings that consist of 167 guest rooms are equipped with Unilux vertical fan coil units. The guest room units are supplied by central chilled water and hot water.

AirRevive conducted a site survey. AirRevive determined 84% of the guest room fan coil units were not operating as designed.

Respecting the hotel’s high occupancy, AirRevive constructed a schedule to accommodate both the hotel and their guest’s occupancy needs and complete the job within 21 days .

COIL TEMPERATURE CHALLENGES:

AIRFLOW CHALLENGES:

NOISE

PROJECT GOALS:

AirRevive’s fan coil unit refurbishment process included the following:

Coil temperature before and after service

The graph below is sorted by coil temperature from high to low before service.

Beginning from the left side the red line depicts coil temperature cooling ranging from 62 ℉ to 44.4 ℉, averaging 51.4℉.

The blue line demonstrates that after the coil rejuvenation and valve replacement coil temperature cooling ranged from 54 to 42 ℉. This resulted in an average coil temperature drop of 8% or 4.1 ℉ from 51.4 to 47.3 ℉.

The AirRevive refurbishment resulted in the coil and fins operating at “as-new” performance.

Lowered coil temperature combined with unrestricted airflow prepares the coils for the EC motor retrofit.

AirRevive’s ECM retrofit included the following:

Airflow before and after service on low setting

The graph below is sorted by airflow from low to high on low setting before service.

The red line is airflow before coil rejuvenation and EC motor retrofit. On the left side it begins at zero. 36 units were found to have zero airflow. The red line’s slope up to the right demonstrates that the units’ airflow before service ranged from 0 CFM to 486 CFM averaging 178 CFM.

The blue line demonstrates an airflow increase of 30% averaging from 178 CFM to 254 CFM. 100% of the unit’s airflow is within the manufacturer’s design curve of 250 CFM – on low setting.

Airflow before and after service on high setting

The graph below is sorted by airflow from low to high setting before service.

The red line is airflow before coil rejuvenation and EC motor retrofit. On the left side it begins at zero. 26 units were found to have zero airflow before rejuvenation. The red line’s slope up to the right demonstrates that the units’ CFM before service ranged from 0 CFM to 595 CFM averaging 234 CFM.

The blue line demonstrates that after the EC motor retrofit airflow increased 49% averaging from 234 CFM to 458 CFM. 100% of the unit’s airflow is within the manufacturer’s design curve of 450 CFM – on high setting.

EC motor retrofit reduces energy consumption

In its “EC motor best practice case study”, AirRevive demonstrates that its refurbishment including coil rejuvenation is the best practice to retrofit EC motors. The highest efficiencies are attained by optimizing the coil prior to retrofitting the EC motor. This is because of the following benefits: Airflow is optimized; and coil temperature is lowered. It is the best practice to have all the buildings fan coil units clean, working uniformly and optimized before programming an EC motor.

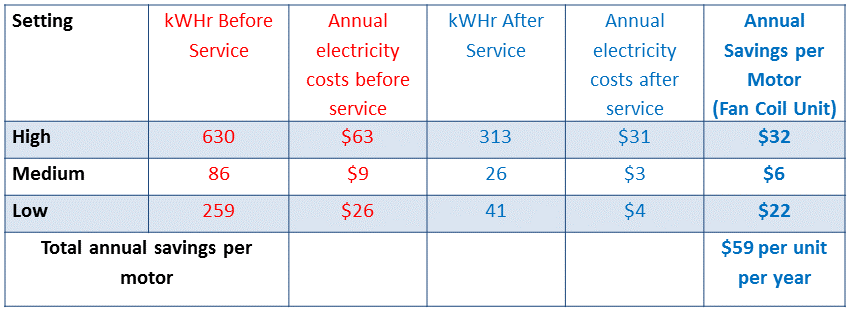

In this project, the re-commissioned units reduced wattage by 84 percent on low, 69 percent on medium and 51 percent on high setting.

The EC motor retrofit resulted in the facility’s fan coil units consuming 60 percent less energy with a savings of about $10,000 per year.

The EC motor retrofit on an AirRevive refurbished unit is the proven best practice for re-commissioning fan coil units. If the coils are not working uniformly before installing EC motors then the EC motor program will not be optimized.

The combination of aged motors, loose parts and components and degraded insulation resulted in noisy units.

The graph below is sorted by sound decibels from high to low before service.

Beginning from the left side the red line depicts sound decibels ranging from 80 to 57 decibels averaging 64.6 decibels.

The blue line demonstrates that after service average sound decibels decreased by 9% from an average of 64.6 to 58.8 decibels.

The result is units that are performing “as-new.” The EC motor retrofit enhanced the units’ operation to better than new by:

FACILITY BENEFITS

The return on investment: The hotel is now consuming 60% less energy on its fan coil units. The units’ performance is better than new, reducing customer complaints and service calls. Guest satisfaction scores are enhanced. The hotel recently experienced some of the hottest and humid weather on record in the mid-Atlantic and the guestrooms cooled as designed. The asset owner saved a few million dollars compared to replacements.

Impact on hotel operation:

The hotel, which is at about 96% occupancy daily, experienced no downtime as rooms were taken out in the morning and returned to service that evening or latest by the following morning. Service was completed within 21 days.