Little Rock Marriott

From American Idol to grand weddings, the Little Rock Marriott hosts guests from all over the world with one focus: guest comfort.

Marriott engaged AirRevive to refurbish the property’s 450 Whalen fan coil units after its $16 million dollar renovation in 2014. The renovation included upgrading the guest rooms to Marriott’s new design. The only former asset remaining was the 1980 Whalen fan coil units.

Fan Coil Units Manufacturer: Whalen

Model#: W304

Project Scope of Work: Guest room vertical fan coil unit refurbishment

Challenge: Dirty coils and fins prevented proper heating and cooling. Dust and debris from the guest room renovation was lodged between the fins, in the motors, and in the blower assembly. The condensate pan was corroding and rusting. The drain lines were clogged.

- Coil temperature averaged 51.56℉.

- 85% of the unit’s coil temperature was above 50 ℉.

- Supply temperature averaged 54.5℉.

- 90% of the unit’s supply temperature was above 52 degrees.

- Airflow averaged 785 FPM.

Solution:

- Rejuvenate coils to increase airflow. Deep clean the coils and fins to enhance heat transfer and extend the life of the existing unit. Coil rejuvenation reduces coil and supply temperature;

- Extend the life of the units by de-rusting and re-coating the condensate pan;

- Clean and disinfect the blower assembly and wheel;

- Clear out, clean and disinfect the drain line; and

- Replace fiber insulation with anti-microbial fiber-free foam insulation.

Results

- The coil temperature dropped 4℉ from an average of 51.6℉ to 47.4℉.

- 73% of coil temperatures were below 49.9 ℉.

- The supply temperature dropped 4℉ from an average of 54.5℉ to 50.8℉.

- 90% of supply temperatures were below 54℉.

- Airflow increased by 22% from an average of 785 FPM to 985 FPM.

- The coil rejuvenation resulted in unrestricted airflow in 100% of the units.

The units were brought back to as-new operation in terms of airflow and heat transfer.

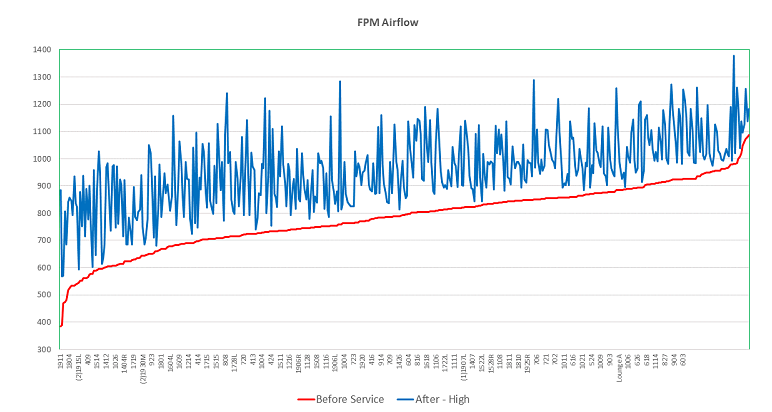

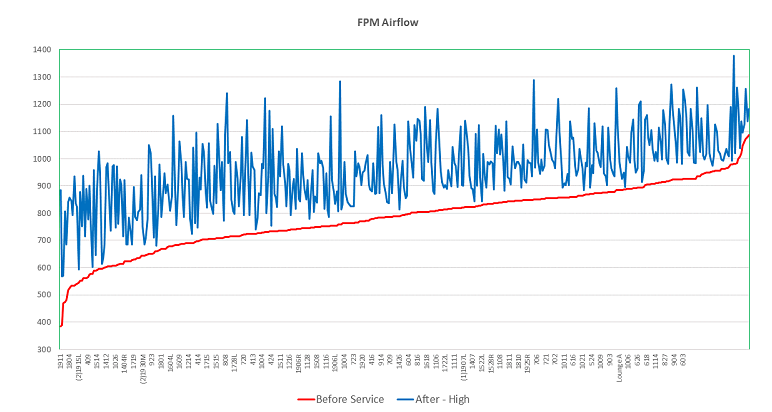

Before & After Airflow Data

The graph below displays the before and after FPM airflow on high fan setting. The red line from left to right demonstrates the airflow before service from low to high ranging from 398 FPM to 1090 FPM. The blue line demonstrates the airflow after service is within the manufacturer’s design target. The horizontal axis represents the room numbers.

Before & After Coil Temperature

The graph below shows coil temperature sorted from high to low before coil rejuvenation. The red line demonstrates before the coils were rejuvenated the coil temperature ranging from 60℉ to 50℉. The blue line demonstrates that after the coils were rejuvenated the coil discharge temperature for 98% of the units is below 50℉. The average coil temperature after service is 47.4℉.

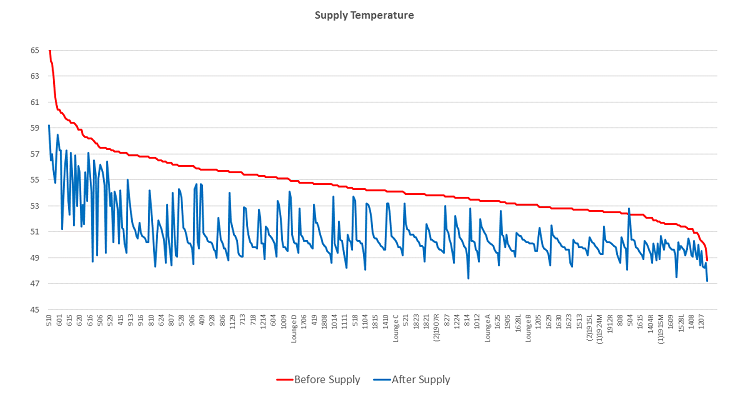

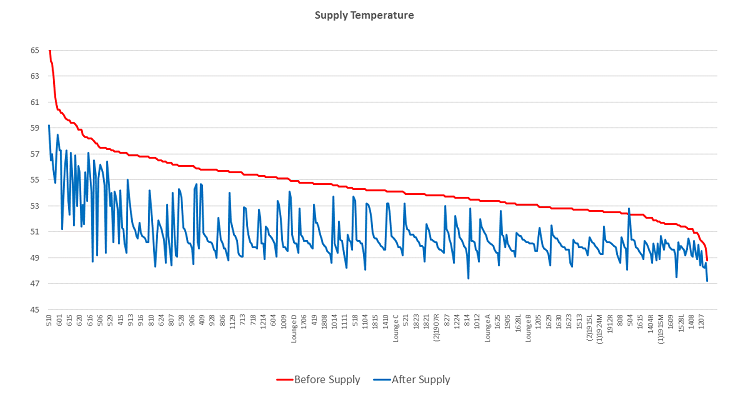

Before & After Supply Temperature Data

The graph below displays before and after supply temperature. The red line from left to right demonstrates the supply temperature before service from high to low ranging from 65 degrees to 49 degrees. The blue line demonstrates the supply temperature after service averaging 50.8 degrees. The horizontal axis represents the room numbers.