Hilton Salt Lake City Center

Perfect for both business and leisure travelers, the Hilton Salt Lake City Center is within walking distance to restaurants, local attractions and the convention center.

The hotel engaged AirRevive to refurbish and re-commission 103 guest room fan coil units in 2016, completing the remainder in 2017. The units were manufactured in 1983.

Fan Coil Units Manufacturer: Unilux

Models#: SC350, SC450, SC600

Project Scope of Work: Guest room vertical fan coil unit refurbishment and EC motor retrofit.

Challenges: The project challenges included: dirty coils; ripped and worn fiber insulation; and airflow outside of the manufacturer’s design curve. The units were noisy specifically on high fan. Medium fan was wired to low fan allowing for only high and low fan options.

- Coil temperature averaged 57.7℉.

- 90% of the unit’s coil temperature was above 53 ℉.

- Supply temperature averaged 62.6℉.

- 99% of the unit’s supply temperature was above 55 ℉.

- Sound decibels averaged 62.3 dB (60 decibels is the highest industry accepted level).

- On the three unit types, each type was outside of the manufacturer’s design curve:

- Airflow on the 385 CFM design averaged 476 CFM on high setting.

- Airflow on the 475 CFM design averaged 352.63 CFM on high setting.

- Airflow on the 590 CFM design averaged 265 CFM on high setting.

Solutions: The refurbishment solution included the following:

- Refurbish and apply epoxy to the condensate pan; clean;

- Disinfect the blower assembly and wheel;

- Clear out, clean and disinfect the drain line; and replace fiber insulation with anti-microbial fiber-free foam insulation; and

- Coil rejuvenation from the front to back to deep in the core resulted in lowered coil temperature and unrestricted airflow preparing the coils for the EC motor retrofit.

The EC motor retrofit solution included programming the EC motor within the manufacturer’s design specifications to produce airflow sufficient to cool and heat the space. Low and medium speed were originally wired together only allowing for low and high speed. The motor was rewired to three separate connections high, medium and low to accommodate the EC motor retrofit. Medium fan was programmed to produce about 10% less airflow than high fan.

Results

- Coil temperature dropped by 6.2 degrees from an average of 57.7℉. to 51.4℉.

- 92% of coil temperatures are below 53℉.

- Supply temperature dropped by 5.2 degrees from an average of 62.6℉. to 57℉.

- The average sound decibels decreased by 8% from an average of 62.33 dB to 57.48 dB.

- The airflow was brought within the manufacturer’s design curve on high, medium and low fan across all unit types.

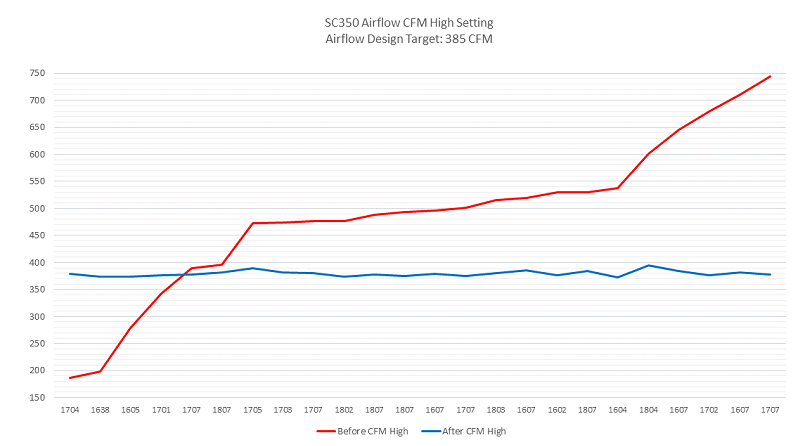

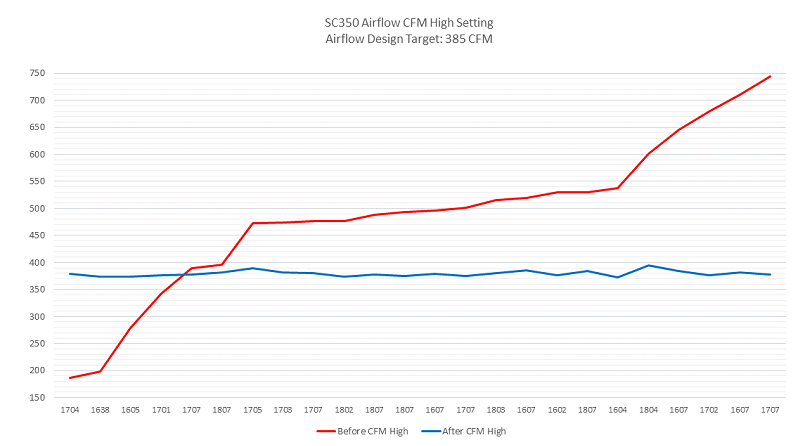

Model SC350:

- Airflow on the 385 CFM design on high setting was brought from an average of 488.31 CFM to 379.46 CFM.

- Airflow on the 310 CFM design on medium setting was brought to an average of 315.52 CFM.

- Airflow on the 260 CFM design on low setting was brought to an average of 269.22 CFM.

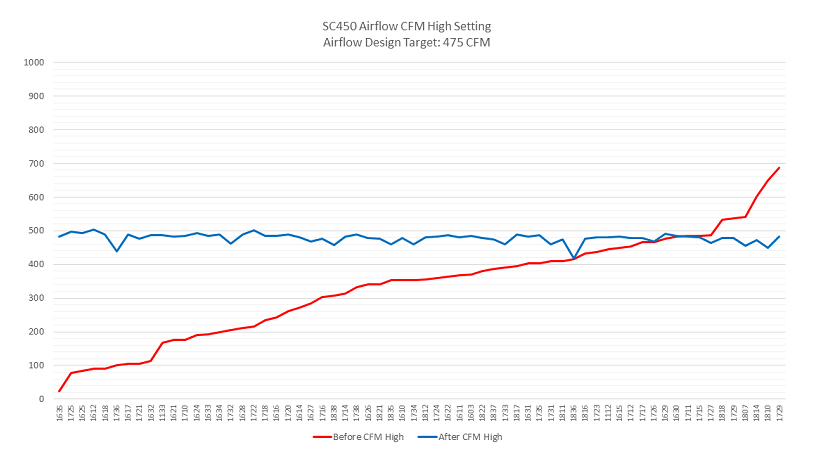

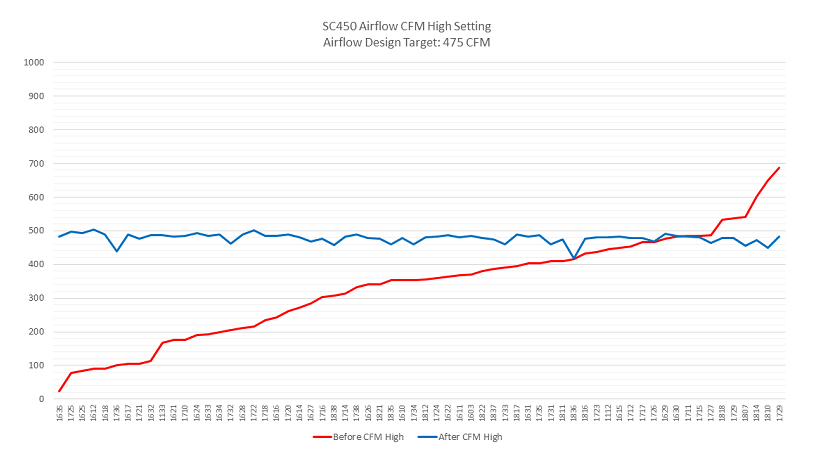

Model SC450:

- Airflow on the 475 CFM design on high setting was brought from an average of 347.59 CFM to 478.27 CFM.

- Airflow on the 390 CFM design on medium setting was brought to an average of 388.26 CFM.

- Airflow on the 300 CFM design on low setting was brought to an average of 305.86 CFM.

Model SC600

- Airflow on the 590 CFM design on high setting was brought from an average of 265 CFM to 536.21 CFM

- Airflow on the 490 CFM design on medium setting was brought to an average of 453 CFM.

- Airflow on the 350 CFM design on low setting was brought to an average of 332.78 CFM.

Before & After Airflow Data

The graphs below display the three unit types’ before and after airflow on high fan setting. The red line from left to right demonstrates the airflow before service from low to high ranged between 190 CFM and 750 CFM. The blue line demonstrates the airflow after service within the manufacturer’s design curve. The horizontal axis represents the room numbers.

Before & After Supply Temperature Data

The graph below displays all unit types’ before and after supply temperature. The red line from left to right demonstrates the supply temperature before service from high to low ranged from 57 degrees to 72 degrees. The blue line demonstrates the majority of the units’ supply temperature after service averaged 57 degrees. The horizontal axis represents the room numbers.